Power cables built for industrial applications require consistent attention to maintain durability and efficiency. Electrical failures due to neglected cables result in expensive downtime and dangerous working conditions.

Preventing premature wear involves structured inspections, careful handling, and proper storage solutions. A proactive maintenance strategy employing some of these eight tips provides long-term reliability and uninterrupted performance in high-demand environments.

Perform Regular Visual Inspections

Small defects quickly escalate into major electrical hazards when left unchecked. Examining insulation for abrasions, punctures, or visible wear prevents damage from reaching the conductors.

Discoloration or exposed wiring indicates internal degradation and often requires immediate replacement. Conduct thorough inspections before and after to maintain consistent performance and prevent unexpected failures.

Loose or corroded connectors disrupt power transfer and create overheating risks. Cleaning terminals and inspecting contact points preserve electrical efficiency and prevent hazardous resistance buildup.

Additionally, faulty fittings lead to power fluctuations. Secure connections should be a top priority in your maintenance routines. One essential tip for maintaining prefabricated NEMA power cables is to regularly check for loose, damaged, or deteriorating connectors to prevent performance failures.

A properly matched strain relief prevents excessive bends that lead to internal wire fatigue and failure. Secure fittings keep cables stable under heavy loads, which reduces the risk of disconnections. Industry-specific strain reliefs accommodate different levels of movement and ensure flexibility without affecting durability. A choice of application-specific designs minimizes wear and extends the overall service life of prefabricated NEMA power cables.

Store Cables Properly To Prevent Damage

Improper storage techniques cause tangles, weaken cables, and permanently damage them. Coil cords correctly by removing sharp bends that weaken internal wiring and shorten the lifespan of industrial-grade cabling.

Also, keep cables in a dry, temperature-controlled location to reduce environmental wear and improve long-term functionality. Organized storage using labeled bins or designated racks lets you quickly identify proper cables and avoid wasting time.

Avoid stacking heavy equipment or materials on top of cables, as that can create hidden pressure points that damage insulation and conductors. Separate stored power cords from high-traffic areas to minimize accidental crushing or stretching.

Additionally, identify each cable’s voltage and application details to reduce errors during setup and prevent compatibility issues. A structured storage approach increases workplace efficiency while preventing unnecessary damage.

Keep Cables Clean and Free of Debris

Contaminants such as dust, grease, and industrial residue interfere with power transmission and degrade insulation. Wiping cables with a dry or slightly damp cloth removes particles without damaging protective coatings.

Manufacturer-approved cleaning solutions safely dissolve stubborn buildup without causing chemical deterioration. Avoid unapproved solvents to preserve structural integrity.

Connectors clogged with dirt or corrosion create weak electrical contacts and increase resistance. Cleaning contact points with electronic-safe solutions maintains steady voltage flow and prevents overheating.

Finally, ensure cables remain dry after cleaning to avoid issues like trapped moisture. Following effective tips for maintaining prefabricated NEMA power cables prevents unnecessary power disruptions caused by poor maintenance and debris buildup.

Avoid Overloading and Overbending Cables

Exceeding the rated electrical capacity of a power cable leads to dangerous overheating and system failures. Equal distribution of power loads across multiple cables prevents unnecessary stress on individual conductors.

Monitor temperature fluctuations in heavily loaded cables to confirm safe operation under industrial demands. A well-balanced electrical distribution approach extends the life of prefabricated NEMA power solutions.

Forcing cables into extreme bends compromises internal wiring and increases the risk of short circuits. Maintain a proper bend radius that’s free of excessive stress on insulation and conductors.

In addition, securing power cables with guides or supports keeps wires in safe operating positions. Structured handling practices protect equipment from unnecessary wear while ensuring consistent performance.

Use the Right Connectors and Accessories

Cables equipped with incompatible connectors fail to deliver optimal performance and increase system inefficiencies. Always use manufacturer-approved accessories to secure connections and minimize voltage drop risks.

Checking specifications before installation prevents mismatches that could lead to poor power transfer. Properly rated connectors maintain safety standards and also prevent electrical arcing.

Additionally, replacing worn-out or damaged connectors before failure occurs eliminates unexpected downtime. Inspect plug ends for signs of wear to prevent disruptions caused by loose or corroded terminals. Tightening loose fittings restores efficiency and reduces resistance-related heat buildup.

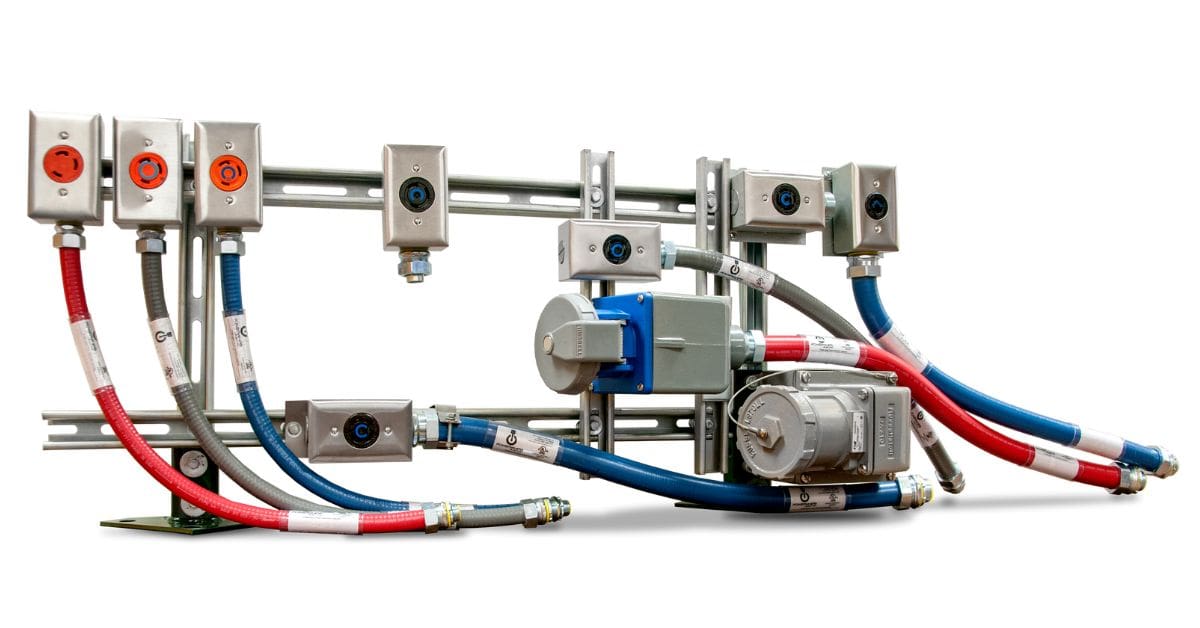

Electrol Powerwhips provides high-quality NEMA power cord and cable equipment built for industrial demands. Prioritizing high-quality connectors prevents avoidable power loss and extends cable longevity.

Monitor Temperature and Environmental Conditions

Extreme heat weakens insulation and accelerates material degradation, leading to early cable failure. Keep cables away from direct heat sources, such as industrial equipment, unless they are heat resistant.

Monitoring ambient temperature in high-power applications lets you verify that cables operate within safe limits. Protective sheathing enhances resistance against heat exposure and mechanical wear.

Moisture infiltration is another environmental issue that increases conductivity and corrosion on internal components. Sealing connections with weather-resistant covers minimizes exposure to humidity and contaminants.

Install power cables in controlled environments to extend their lifespan and prevent performance fluctuations.

Replace Worn or Damaged Cables Immediately

Aging or damaged cables create major electrical hazards when left in service too long. Frayed insulation, exposed wiring, or intermittent power failures indicate the need for immediate replacement.

Continued use of a compromised cable raises your risks of electrical shorts, power surges, or even fire hazards. Swapping out unreliable power cords promotes workplace safety and uninterrupted operation.

Always disposing of outdated cables according to industry regulations prevents hazardous material mishandling. Test any suspected faulty cable before replacing it by confirming the issue to prevent wasting cables and time troubleshooting the wrong cords.

Keeping spare cables on hand allows for quick swaps without delaying production. Additionally, consulting professionals is an easy way to maintain industry compliance and handle more complex replacements.

Rely on Professional-Grade NEMA Power Cables

Dependable prefabricated solutions provide safety, durability, and performance across various applications. Strict adherence to industry standards guarantees cables function reliably in high-powered environments. Investing in professional-grade equipment prevents failures caused by low-quality alternatives.

Choose properly manufactured power cables to eliminate risks associated with inconsistent or subpar materials. Prefabricated options designed for industrial use provide superior reliability under intense workloads.

A proactive approach to maintaining power cables increases their reliability, safety, and cost savings in industrial applications. Small adjustments in handling, storage, and monitoring make a significant impact on cable longevity. Professional-grade solutions provide lasting durability and minimize downtime by preventing unnecessary replacements.

Expert guidance ensures businesses select cables suited to specific power demands. Electrol Powerwhips provides expert advice on selecting and maintaining the best NEMA power cables for industrial operations. Contact us today for tailored solutions for optimizing efficiency and reducing long-term equipment failures.