When it comes to powering modern facilities, selecting the right electrical distribution system is critical for operational efficiency, reliability, and scalability. Two common systems dominate the conversation in this space, and the decision between busbar systems versus power whips often comes down to specific requirements, application context, and long-term priorities. To make an informed choice, it’s essential to understand how these systems function, where they excel, and what challenges they might pose.

Understanding Busbar Systems and Power Whips

Busbar systems are encapsulated structures consisting of copper or aluminum conductors housed within protective enclosures, often modular in design. Their primary function is to deliver power to various points in a facility with precision and efficiency. These systems are most often used in large-scale application environments, including industrial plants and high-rise buildings. Their sleek, low-profile design makes them a favored choice when aesthetics or tight spatial constraints are critical to the business.

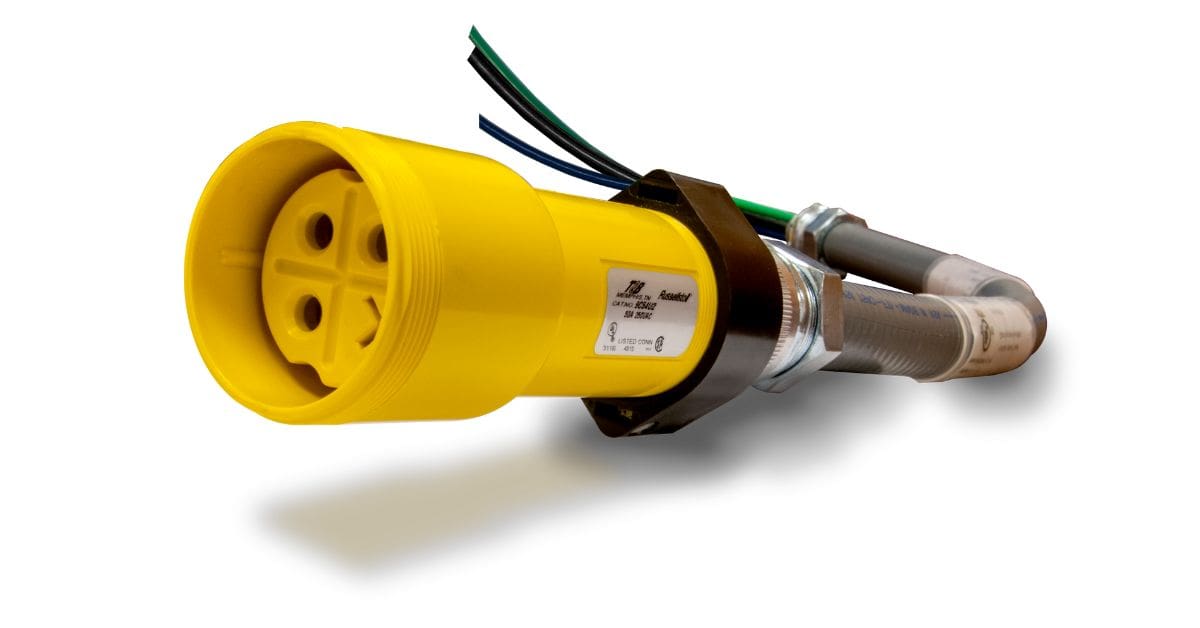

On the other hand, power whips are flexible electrical conduits typically used to connect equipment to a power source. Unlike the rigid structure of the busbar system, power whips are adaptable and easily navigable through highly complex and crowded spaces. This flexibility is a standout advantage in scenarios where precision installation and equipment mobility are a priority. Power whips are often widely used in facilities like data centers, where adaptability and modular setups are a constant priority due to frequent equipment changes.

Installation Process Considerations

The installation process is often a deciding factor when choosing between these systems. Busbar installations typically involve a significant initial investment in terms of time, resources, and skilled labor. Their modular nature does make assembly straightforward, but the rigidity of the system can make it challenging in environments where layouts constantly shift or expand regularly. The complexity of securing the busbar infrastructure to an existing space can increase both the project timeline and associated costs.

Power whips, on the other hand, have a more straightforward and cost-effective installation process. Their design allows for quick deployment, even in locations with dense and entangled physical infrastructure. Minimal disruption to existing systems and reduced labor requirements make power whips an appealing option for businesses aiming to save both installation time and money. The lightweight and flexible nature of power whips remains ideal for companies seeking efficient power delivery without overcomplicating facility operations.

Scalability and Flexibility in Action

One of the most significant considerations when choosing a distribution system is its ability to adapt to changing power needs. Busbar systems excel in fixed setups that periodically require incremental scalability. Their structured and linear format is suitable for predictable growth patterns, making them advantageous for facilities with clearly defined layouts that rarely change over time.

Power whips, however, shine in environments where versatility is essential. Their inherent adaptability gives businesses the ability to adjust power delivery based on evolving arrangements and layouts. Whether equipment is regularly reconfigured, expanded, or completely replaced, power whips allow for seamless transitions without extensive infrastructure changes or renovations.

Maintenance Requirements and Operational Downtime

The ongoing maintenance of electrical systems can critically impact operational efficiency over time. Busbar systems, while reliable, require expert handling during repairs or upgrades. Unscheduled maintenance often calls for system shutdowns, leading to downtime that can be disruptive in high-demand environments. Regular inspections, detailed knowledge of the modular structure, and periodic updates can incur substantial costs and take up more time.

Power whips carry significant advantages when it comes to maintenance. Their simpler structure means issues can be resolved quickly without requiring advanced technical expertise. The modular design of power whips also ensures that any necessary repairs can typically be done incrementally, avoiding the prolonged downtime sometimes associated with busbar systems. This ease of maintenance is another reason businesses often prefer power whips for managing their operations seamlessly.

Regulatory Standards and Safety Compliance

Safety and regulatory compliance are nonnegotiable elements in any electrical system deployment. Both busbar systems and power whips must adhere to industry standards that involve electrical distribution, materials, and installation practices. However, some differences stand out. Busbar systems, with their enclosed structures, provide excellent protection against accidental contact and exposure to electrical faults, which makes them a dependable solution in settings where safety takes priority.

Power whips, while inherently flexible, are designed with robust materials to prevent potential hazards. Modern power whips meet stringent safety regulations, offering excellent insulation properties and durable construction to reduce risks.

Short-Term and Long-Term Costs

Initial and long-term costs are significant factors that influence system selection. Busbar systems often carry higher upfront costs due to their extensive material and labor demands. Their fixed nature can limit their ability to adjust cost-effectively in rapidly evolving environments. Maintenance costs, which can add substantial expenses over the system’s lifespan, must also be factored in.

Conversely, power whips stand out for their lower initial cost of materials and quicker installation timelines. Furthermore, their adaptability significantly reduces the need for large-scale overhauls when business requirements change. Long-term operational costs are typically lower as well, as power whips minimize downtime and maintenance expenses.

Electrol PowerWhips offers a wide range of premium electrical whips designed to handle even the most demanding power needs. Built for durability and flexibility, our products are specifically crafted to support the growth and reliability of your business. Reach out to our team today and ensure your operations stay powered under any circumstances.

Clarifying Common Misconceptions

A common belief is that busbar systems are universally superior due to their structured design and aesthetic appeal. While this may hold true in certain architectural contexts, their rigidity can limit their functionality in spaces requiring regular adaptability. Similarly, some view power whips as less durable or less capable of handling high electrical loads. However, today’s power whips are engineered with advanced materials and standards to meet robust performance requirements and are highly reliable in diverse applications.

It’s also worth clarifying that power whips are far from a temporary solution, as they are sometimes incorrectly perceived. Their modern construction and advanced features make them perfectly capable of serving as long-term electrical distribution systems in a variety of scenarios.

Deciding Which System Best Suits Your Needs

When weighing the benefits of busbar systems versus power whips and deciding which system to choose, evaluate the specific operational needs, budget, and scalability of your business first. For businesses valuing adaptability, cost-effectiveness, and simple maintenance, power whips provide a practical and efficient solution that grows alongside operational changes. Their ability to balance flexibility with durability eliminates some of the most significant challenges posed by more rigid and complex alternatives. Make the smart choice and experience how this innovative system can simplify electrical distribution.