The world of power infrastructure is constantly evolving, driven by the need for greater efficiency, safety, and reliability. At the heart of this transformation is prefab power cable manufacturing, an industry undergoing rapid innovation. New technologies and processes are redefining how power cables are made, installed, and maintained.

These innovations are making electrical projects faster, safer, and more cost-effective. As we look at the innovations transforming prefab power cable manufacturing, it’s clear that the industry is moving toward a smarter, more integrated future. We’ll explore the key technologies driving this change and what they mean for the industry.

The Role of Automation and Robotics

One of the most impactful trends in prefab power cable manufacturing is the integration of automation and robotics. In the past, many stages of cable production relied on manual labor, which could introduce variability and human error. Today, automated systems are taking over repetitive, precision-intensive tasks, setting a new standard for quality and consistency.

Enhancing Precision in Production

Robots excel at performing tasks that require high precision, such as wire drawing, insulation extrusion, and cable stranding. For instance, automated systems can maintain exact tension levels and consistent speeds during the manufacturing process.

This precision yields cables with uniform electrical properties and mechanical strength, critical for reliable performance in demanding applications. Automated quality control uses sensors and machine vision to inspect cables for defects in real-time, identifying issues that the human eye might miss.

Boosting Safety and Efficiency

Manufacturing power cables can involve hazardous materials and heavy machinery. By automating these processes, manufacturers reduce the risk of workplace accidents and create a safer environment for their employees.

Additionally, robots can operate 24/7 without fatigue, which dramatically increases production output. This efficiency allows manufacturers to meet growing demand and shorten lead times for complex projects, providing a competitive advantage in a fast-paced market.

Advancements in Material Science

The materials used in power cables are just as important as the manufacturing process itself. Recent breakthroughs in material science are leading to the development of cables that are more durable, efficient, and environmentally friendly. These new materials are designed to withstand harsh conditions and deliver superior performance over their lifespan.

High-Performance Polymers and Composites

Researchers are creating advanced polymers and composite materials for cable insulation and jacketing. These materials offer enhanced thermal stability, chemical resistance, and mechanical toughness. For example, new cross-linked polyethylene (XLPE) compounds can operate at higher temperatures without degrading, thereby increasing power transmission capacity.

Similarly, specially formulated PVC and thermoplastic elastomers offer superior flexibility and flame-retardant properties, making them suitable for a wide range of industrial and commercial applications.

The Rise of Sustainable Materials

Sustainability is a growing priority across all industries, and power cable manufacturing is no exception. Companies are exploring eco-friendly materials, such as bio-based polymers and recyclable thermoplastics, to reduce their environmental footprint. These green materials help manufacturers meet regulatory requirements while appealing to customers who are increasingly focused on sustainability.

The development of halogen-free, flame-retardant (HFFR) compounds, for example, minimizes the release of toxic gases in the event of a fire, enhancing safety while being better for the environment.

The Impact of Digitalization and IoT

The digital revolution is reshaping manufacturing, and prefab power cable production is embracing this trend. The Internet of Things (IoT), data analytics, and digital twin technology are creating “smart factories” where every aspect of the production process is monitored, analyzed, and optimized. This connectivity provides unprecedented levels of control and insight.

Real-Time Monitoring and Data Analytics

IoT sensors embedded in manufacturing equipment collect vast amounts of data on everything from machine performance to environmental conditions. This data is then analyzed to identify trends, predict maintenance needs, and optimize production parameters.

For instance, predictive analytics can forecast when a piece of machinery is likely to fail, enabling proactive maintenance to prevent costly downtime. Real-time monitoring also provides a complete digital record of the manufacturing process, which improves traceability and quality assurance.

Digital Twins for Design and Simulation

Digital twin technology involves creating a virtual replica of a physical product or process. In prefab power cable manufacturing, engineers use digital twins to design and simulate cable performance before a single physical component is produced.

This allows them to test different materials, configurations, and environmental conditions in a virtual environment, thereby accelerating the design cycle and reducing development costs. Digital twins also help optimize the manufacturing process by simulating different production scenarios to find the most efficient approach.

Modular Designs and Customization

Prefabrication’s core advantage is its ability to streamline installation by moving construction tasks from the field to the factory. Modern prefab power cable systems are taking this a step further with modular designs that offer even greater flexibility and ease of use. These systems are designed for plug-and-play installation, which drastically reduces on-site labor and project timelines.

Plug-and-Play Systems

Modular power cable assemblies come with pre-installed connectors, terminators, and other components, arriving on-site ready for immediate installation. This approach eliminates the need for specialized labor and time-consuming tasks like cable stripping and crimping. For large-scale projects such as data centers or industrial plants, modular systems can cut installation time by more than half. The result is a faster, more reliable installation with fewer potential points of failure.

Tailored Solutions for Specific Needs

Modern manufacturing enables high customization without sacrificing efficiency. Using advanced design software and flexible production lines, manufacturers can create bespoke cable solutions tailored to a project’s unique requirements.

Whether it’s a specific length, connector type, or jacket color, custom prefab cables can be produced quickly and cost-effectively. This level of personalization enables optimizing power systems for performance, space, and aesthetics.

A More Connected and Efficient Future

The innovations transforming prefab power cable manufacturing are creating a new era of efficiency, quality, and sustainability. Automation, advanced materials, and digitalization are working together to produce superior products that meet the evolving demands of the modern world.

These advancements not only improve the performance of power cables but also make the manufacturing and installation processes safer and more cost-effective. As these technologies continue to mature, we can expect even greater progress in the years to come.

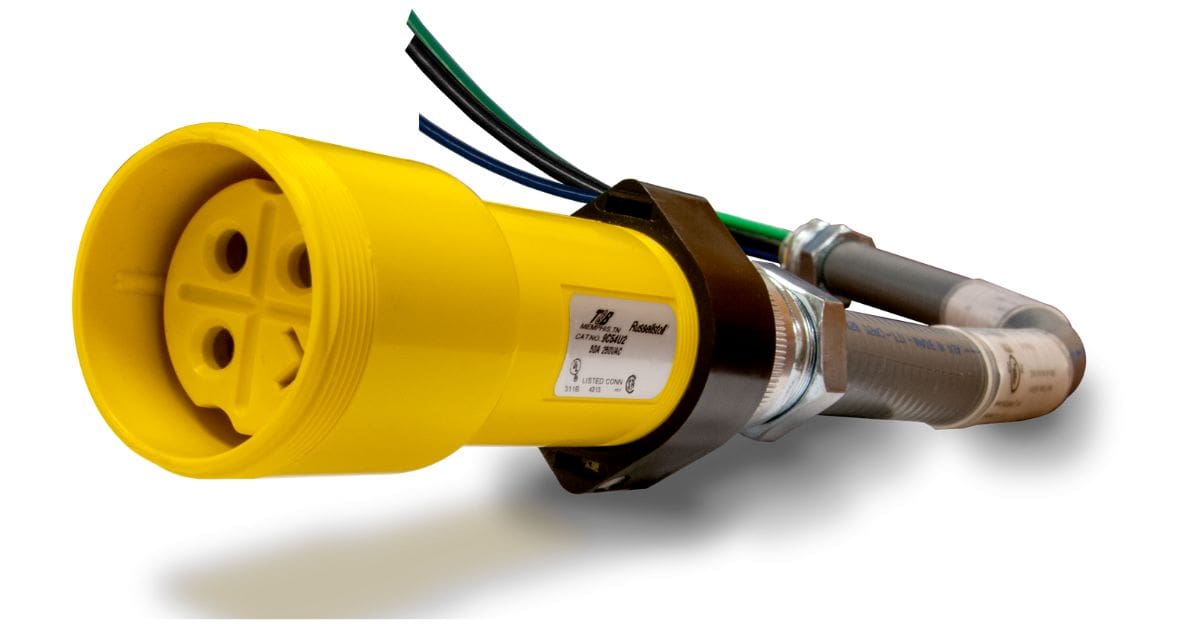

For businesses looking to leverage these advancements, partnering with a forward-thinking manufacturer is key. At Electrol Powerwhips, we specialize in providing high-quality components like a Russellstoll receptacle and beyond, ensuring your operations are equipped with the tools needed to embrace the latest innovations. Let us help you streamline your processes, enhance efficiency, and power your business into the future.