Choosing components for high-current industrial applications demands precision and a deep understanding of electrical systems. When selecting interconnect solutions, few choices have greater implications for safety and operational reliability than deciding between a three-phase, three-wire (3P3W) and a three-phase, four-wire (3P4W) configuration.

Our analysis clarifies the technical distinctions between choosing a 3P4W versus a 3P3W Russellstoll for high-current loads, ensuring your industrial operations remain efficient and reliable.

Understanding the Core System Architectures

Before evaluating specific product lines, it is essential to comprehend the fundamental differences between these two wiring systems. The presence or absence of a neutral conductor alters how power is delivered and how electrical loads are supported.

The 3P3W (Three-Phase, Three-Wire) System

A 3P3W system consists of three phase conductors (L1, L2, L3) and an equipment grounding conductor (EGC). It does not include a dedicated neutral wire. This configuration is engineered to serve balanced three-phase loads, where the current draw across all three phases is equal.

This system is commonly specified for large, three-phase motors, pumps, fans, and other industrial machinery that operate solely on phase-to-phase voltage. Its primary advantage is simplicity! Using fewer conductors reduces material costs and simplifies electrical installation.

The 3P4W (Three-Phase, Four-Wire) System

A 3P4W system includes three phase conductors, a neutral conductor, and an equipment grounding conductor. The inclusion of the neutral wire greatly enhances the system’s versatility. It allows the circuit to supply both three-phase (phase-to-phase) loads and single-phase (phase-to-neutral) loads from the same power source.

For instance, in a 480Y/277V system, the voltage between any two phases is 480V, while the voltage between any phase and the neutral is 277V. This enables a single connection to power a large three-phase motor while also supplying power to 277V lighting or control circuits integrated into the same machine.

Evaluating Load Requirements for Proper Specification

The primary factor in making this decision is the nature of the electrical load itself. The equipment’s power requirements dictate the necessary circuit configuration.

Applications for 3P3W Systems

A 3P3W configuration is the optimal choice for purely balanced loads, but you should consult the equipment nameplate for its electrical specifications. If the nameplate indicates a single three-phase voltage (e.g., “480V 3Ø”) without a slash rating or a “Y” designation, it likely requires only a three-wire connection plus ground.

Using a 3P3W Russellstoll connector in this scenario is efficient and cost-effective. It aligns directly with the equipment’s needs without providing unnecessary conductors. These systems are common in applications involving large induction motors, industrial heaters, and certain types of welding equipment, where no auxiliary single-phase power is drawn from the same circuit.

Applications for 3P4W Systems

Modern industrial machinery often integrates complex control systems alongside high-power motors. A manufacturing cell might have a 480V motor for its primary function but also include a programmable logic controller (PLC), sensors, and operator interface panels that run on 120V or 277V. If these auxiliary components are powered internally from the main feed, a neutral conductor is required.

In these cases, a 3P4W Russellstoll system is mandatory. The equipment nameplate will typically specify a slash voltage, such as “480Y/277V,” explicitly indicating the need for a neutral connection. Attempting to power such equipment with a 3P3W circuit would necessitate adding an external control power transformer at the machine, which adds cost, complexity, and a potential point of failure.

Design and Safety Features of Russellstoll Connectors

Russellstoll connectors are engineered for reliability in harsh industrial environments. Their design incorporates critical safety features for both 3P3W and 3P4W systems.

Mechanical Polarization and Keying

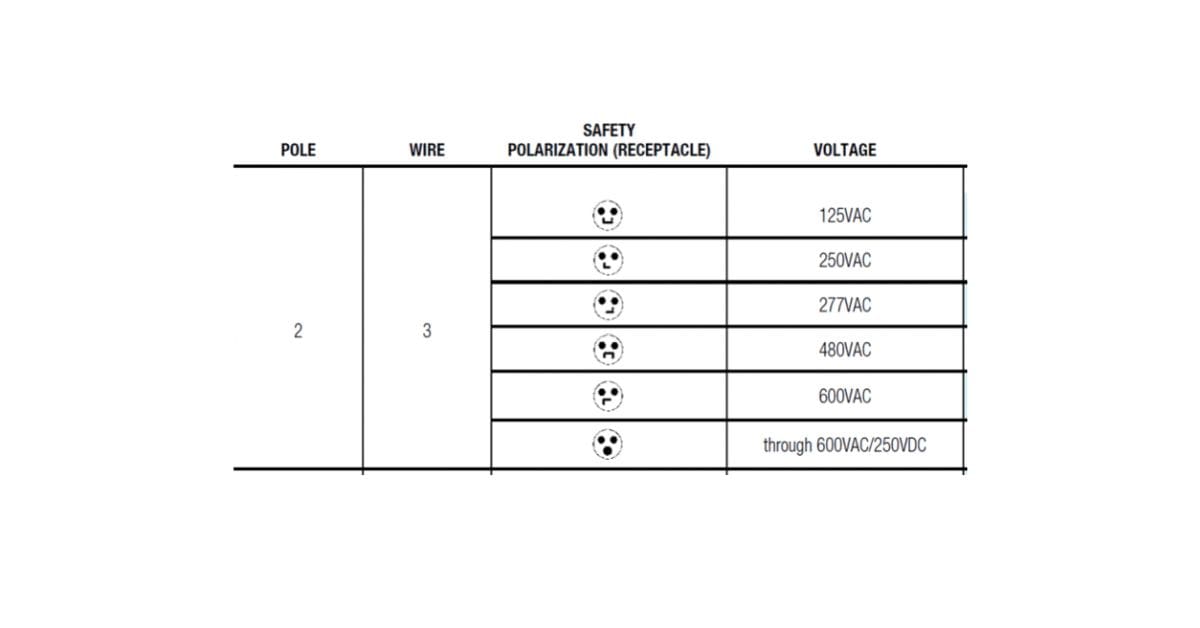

A fundamental safety feature is mechanical polarization. Russellstoll connectors use a “clocking” system in which the position of the ground pin is indexed differently depending on the voltage, amperage, and wiring configuration. This physical keying prevents connecting a plug to an incompatible receptacle, preventing accidental cross-connections that could damage equipment or create a life-safety hazard.

Grounding Integrity and Sequencing

Russellstoll connectors also feature a “make-first, break-last” design for the ground pin. This ensures that a solid ground connection is established before any current-carrying conductors make contact and maintained until after they are disconnected. This principle applies to both 3P3W and 3P4W configurations, protecting personnel from electrical shock in the event of a fault.

Facility Infrastructure and Long-Term Strategy

Your decision should also account for your facility’s existing electrical infrastructure and long-term operational plans.

Aligning With Facility Power Systems

The connector choice must match the upstream power source. Most modern commercial and industrial facilities use a solidly grounded Wye-connected secondary transformer, which provides a neutral conductor. A 3P4W distribution system is the natural extension of this architecture.

If your facility uses an ungrounded or corner-grounded Delta system, there is no neutral, making 3P3W the appropriate configuration. Always verify the source transformer configuration before specifying downstream components.

Standardization and Future-Proofing

While a 3P3W receptacle can only serve 3-wire loads, a 3P4W receptacle can serve both 4-wire loads and 3-wire loads (when used with a 4-wire plug where the neutral terminal is not connected).

Standardizing on 3P4W receptacles for general-purpose high-current outlets provides maximum flexibility. It allows any piece of equipment, regardless of its neutral requirement, to be connected at that location.

Although this approach involves a slightly higher initial cost for the additional conductor, it can prevent expensive retrofits in the future when production lines are reconfigured or new machinery is acquired. This strategy simplifies maintenance inventories and reduces downtime during equipment changes.

Choose the Right System

The process of choosing between a 3P4W versus a 3P3W Russellstoll for high-current loads is a technical exercise in matching the power source to the load’s specific requirements. The 3P3W system offers an efficient, streamlined solution for dedicated, balanced three-phase machinery. In contrast, the 3P4W system provides the necessary versatility for modern, complex equipment that integrates both three-phase and single-phase loads.

To ensure a safe and reliable installation, you must meticulously analyze the equipment nameplate data, verify your facility’s power distribution architecture, and consider your long-term operational needs. Keep in mind that a well-specified connector system is a key factor to a productive and safe industrial environment.

For high-current applications demanding precision and reliability, Electrol Powerwhips offers a Russellstoll connector solution engineered to meet your exact specifications. Contact our technical support team today to discuss your 3P3W or 3P4W requirements and ensure your industrial connections are both safe and efficient. Let us be your trusted partner in delivering safe, efficient, and reliable industrial connections!