IEC 60309 power cords play an indispensable role in keeping generators operating efficiently and safely across a wide range of applications. To select power cords, you must align the technical details with your needs with a focus on long-term reliability and regulatory compliance. When you understand their features, benefits, and installation requirements, you can maximize generator performance and avoid risks or unnecessary costs.

What Are IEC 60309 Power Cords?

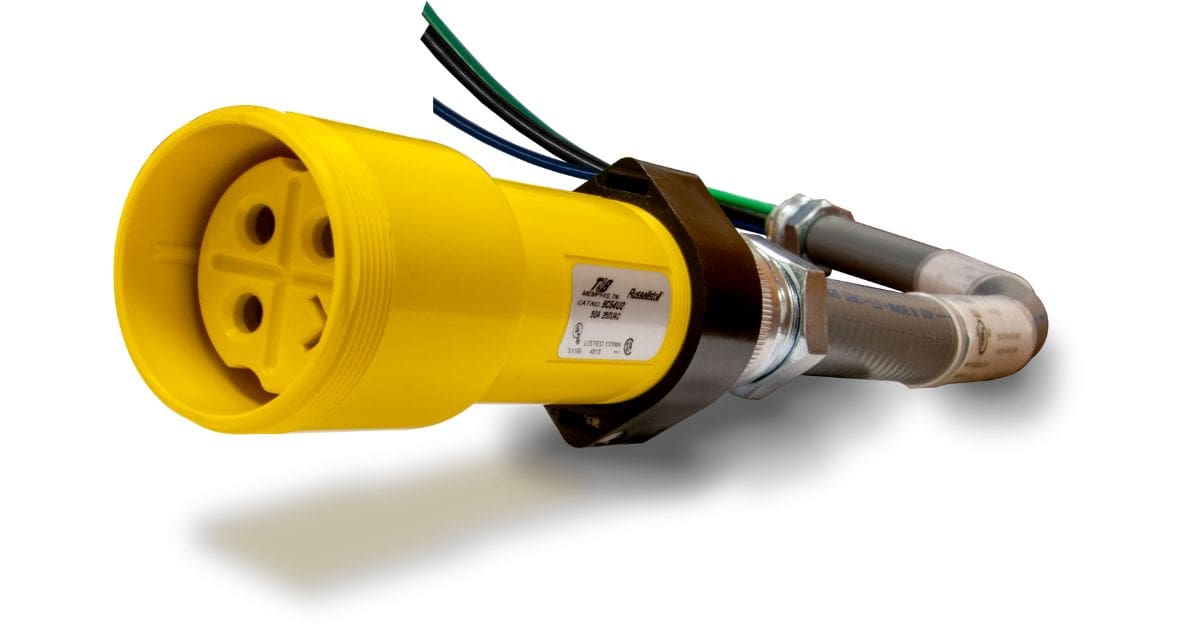

IEC 60309 power cords are globally standardized connectors that handle demanding electrical loads. Their compatibility with diverse equipment is possible due to their adherence to internationally recognized specifications. Whether you’re operating in industrial, commercial, or outdoor environments, IEC 60309 connectors provide a secure and versatile power solution.

Electrol Powerwhips specializes in delivering professional IEC 60309 plug options for facilities requiring consistent and reliable energy transmission. Data center teams depend on these cords for operations where even minor power interruptions could lead to costly downtime. Facility managers can minimize errors and achieve better system performance by selecting appropriate cords for different operations.

IEC 60309 connectors are durable and safe to use. They can handle high levels of power, which is essential for operating heavy machinery or intricate equipment setups. Something you need to know about IEC 60309 power cords for generators is what makes them unique.

Key Features of IEC 60309 Power Cords

IEC 60309 power cords follow a color-coded identification system to simplify setup and reduce the risks of mismatched equipment. Blue connectors indicate compatibility with 230V systems, while red covers 400V. The color code helps you translate complex electrical requirements into straightforward cord selection and saves valuable time during installation.

IEC 60309 cords can withstand extreme temperatures, water exposure, physical impact, and UV rays. For instance, a generator supporting outdoor lighting would benefit from a cord with strong water resistance to avoid short circuits caused by moisture exposure.

Locking mechanisms within IEC 60309 connectors prevent disconnections under pressure or during prolonged use. For instance, when operating heavy equipment at a manufacturing site, a loose connector could lead to sudden power loss and halt operations.

Benefits of Using IEC 60309 Power Cords With Generators

Another thing you need to know about IEC 60309 power cords for generators is that certified cords create a stable connection that minimizes equipment strain and lowers repair costs over time. IEC 60309 power cords mitigate serious safety issues, such as electrical fires or overloaded circuits, that can arise from improperly matched cords.

Connecting a generator to a load exceeding its intended amperage may overheat the cord, melt insulation, and cause short circuits. High electrical loads challenge standard cords and cause intermittent power delivery or unexpected shutdowns.

Generators paired with IEC 60309 cords maintain consistent voltage under demanding conditions, such as powering industrial drill presses or temporary stage equipment at outdoor events. You’ll benefit from the predictable performance that eliminates disruptions in time-sensitive operations.

These power cords also extend generator life by reducing wear caused by incompatible or low-quality cables. Regular cords, on the other hand, lack the resilience to handle the voltage changes and environmental wear of generator use.

How To Choose an IEC 60309 Power Cord for Your Generator

Always match the cord with the generator’s voltage and amperage requirements. For example, a 32A generator powering high-current tools will require a cord rated for that capacity. Missing technical details increases the risk of an overloaded circuit, tripped breakers, or damaged connectors.

Cord length plays an important role, especially when generators are far away from the devices they power. Long cords introduce the possibility of voltage drops, low electrical efficiency, and underperforming equipment. If you’re running power tools 100 feet away from the generator, opt for a cord that compensates for the distance and prevents noticeable power degradation.

Environmental conditions further influence your choice of power cords. Outdoor use demands waterproof designs to prevent moisture from shorting live connections.

If you’re operating a generator at a construction site in rainy conditions, look for a water-resistant and weatherproof cord. Matching the cord’s durability to its environment safeguards operations from interruptions or hazards.

Installation and Maintenance Guidelines

Installing IEC 60309 cords involves a detailed inspection process to confirm every connector meets compatibility and safety requirements. For instance, inserting mismatched connectors can cause misaligned pins that risk shorting or damage upon activation. Verify the alignment and tightness of each connection to prevent issues and maintain stable power flow.

Adopt a proactive maintenance schedule to extend the functionality of your cords. Regular checks for cuts, frays, or insulation damage can help you catch minor problems before they worsen. Spotting corrosion on connectors before use could prevent overheating issues that might otherwise compromise power delivery.

Proper storage adds another layer of protection, particularly in environments with climate extremes. The elements can degrade a cord’s components over time, leading to brittle insulation or rusty connectors. Store the cords in temperature-controlled areas to preserve their integrity for future use.

Safety and Compliance Considerations

IEC 60309 power cords are ideal for use in high-risk environments. Cords in chemical manufacturing plants, for instance, must resist surface pollutants and electrical hazards. Power cords that meet industrial standards create a safer workspace and prevent compliance violations that could result in penalties.

Locking mechanisms add assurance by preventing accidental unplugging that could lead to sudden equipment stops or incomplete operations. Imagine a welding station with a generators losing power mid-process! The inconvenience and wasted raw materials contribute to project waste.

Certifications from suppliers safeguard your operational efficiency, giving you peace of mind about product authenticity and performance. Unverified connectors might lack safety seals, placing your equipment and operators at risk. Purchasing certified IEC 60309 cords guarantees compliance and streamlines your power system management.

Choosing the right IEC 60309 power cords for your generators can transform the way you manage power in demanding environments. By understanding their features and applying them strategically, you gain more functionality and unlock improved safety, uninterrupted workflows, and extended equipment life. Don’t leave your operations to chance!

Electrol Powerwhips specializes in premium IEC 60309 connectors that meet industry needs. Contact Electrol Powerwhips today for expert advice and access to top-quality products that can maximize your generator’s performance and reliability.