Navigating the world of electrical components can be challenging, especially with the various standards and regulations that ensure safety and functionality. However, a deep understanding of electrical standards is crucial for anyone involved in electrical work. To retain safety, the National Electrical Manufacturers Association (NEMA) has established a comprehensive system for classifying plugs and receptacles to prevent unsafe connections.

This guide will explore the essential NEC Code requirements for NEMA receptacles, providing clarity on how these standards apply to different settings and ensuring your installations are both safe and compliant.

The Foundation of NEMA Standards

NEMA standards serve as the foundation for safe and efficient electrical installations across residential, commercial, and industrial use. These standards define the design and functionality of electrical components, ensuring compatibility and reliability in diverse electrical systems.

By adhering to these guidelines, professionals can minimize risks, maintain code compliance, and improve overall system performance. Understanding the foundation of NEMA standards is crucial for selecting the right receptacles and plugs for specific environments and applications.

Defining Electrical Safety and Compatibility

The National Electrical Manufacturers Association develops standards that specify the physical configurations of electrical plugs and receptacles. The primary goal of these standards is to prevent what is known as unsafe interchangeability.

This is achieved by designing unique plug and receptacle shapes for different voltage and amperage ratings, making it physically impossible to connect a device to a power source that it is not intended for.

Straight-Blade vs. Twist-Locking Connectors

NEMA connectors are broadly categorized into two main types: straight-blade and twist-locking. Straight-blade, or non-locking, connectors are the most common type found in residential settings. They allow for quick and easy connection and disconnection.

In contrast, twist-locking connectors, identified by an “L” in their NEMA designation, feature a locking mechanism that secures the plug to the receptacle. This design provides a more reliable and secure connection, making it ideal for industrial environments where vibrations or tension on the cord could otherwise cause accidental unplugging.

NEMA Configurations

NEMA configurations are a standardized system used to identify electrical connectors based on their specific design, voltage, and amperage ratings. Understanding these configurations ensures compatibility and safety when selecting and using electrical equipment in various applications.

The NEMA Numbering System

The nomenclature used for NEMA devices provides specific information about their electrical characteristics. Each code consists of numbers and sometimes letters. The first number indicates the plug’s configuration, which includes its voltage rating and the number of poles and wires.

The second number represents the amperage rating, with common values being 15, 20, 30, 50, and 60 amps. An “R” or “P” suffix denotes whether the device is a receptacle or a plug, respectively.

Common Residential NEMA Types

In residential settings, you will most frequently encounter a few specific NEMA configurations. The NEMA 5-15 is the standard 125V, 15A household outlet. On the other hand, the slightly different NEMA 5-20, rated for 20 amps, is often required by code in areas such as bathrooms and kitchens. For higher-power appliances, such as electric dryers and ranges, NEMA 14-30 and 14-50 receptacles are used. These are four-wire grounding connectors rated for 125/250V.

Key NEC Requirements for Receptacles

When installing electrical receptacles, it is essential to adhere to the standards outlined by the National Electrical Code (NEC). These requirements are designed to maintain safety, compatibility, and functionality in residential, commercial, and industrial settings. Below are some of the key NEC regulations to consider.

Branch Circuit Ratings and Limitations

The National Electrical Code provides strict guidelines for branch circuits. NEC 210.18 mandates that branch circuits must be rated according to the maximum permitted amperage of the overcurrent protection device, such as a circuit breaker.

For circuits that are not dedicated to a single appliance (individual branch circuits), the NEC limits the ratings to 15, 20, 30, 40, and 50 amperes. This means that a standard shared circuit in a home will fall into one of these categories.

Requirements for High-Amperage Receptacles

When it comes to higher amperage installations, such as those for electric vehicle (EV) chargers or large welders, the rules become more specific. NEC 210.18 requires that any 60A receptacle, like a NEMA 14-60R, must be installed on a dedicated, or individual, branch circuit.

This ensures that the high power draw of the connected device does not overload a circuit shared with other outlets. For loads that run for extended periods, known as continuous loads, the current must be limited to 80 percent of the circuit breaker’s rating to prevent overheating and ensure safety.

Special Applications and Considerations

When designing electrical systems, certain applications require additional considerations beyond standard installations. These special cases often involve unique environments, equipment specifications, or specific safety requirements to maintain compliance with the National Electrical Code and optimal system performance.

Receptacles for Electric Vehicle Charging

The growing popularity of electric vehicles has brought NEMA receptacles into focus for home charging. An EV charger, also known as electric vehicle supply equipment (EVSE), can be either hardwired or connected via a plug.

Until recently, a plug-in EVSE was limited to a 50A circuit, providing a usable 40A of continuous power. Still, the NEMA 14-50 receptacle is gaining popularity for home charging capabilities due to its widespread availability and capacity. For higher-power charging, a hardwired EVSE is necessary, which can support up to an 80A continuous load on a 100A circuit.

NEMA Enclosure Ratings for Location Safety

Beyond the plug configuration, NEMA also provides ratings for the enclosures that house electrical components. These ratings define the degree of protection an enclosure provides against environmental factors such as dust, water, and corrosion.

For example, a NEMA 1 enclosure is designed for use in clean, dry, indoor environments. In contrast, a NEMA 3R or NEMA 4X enclosure is designed for outdoor use, offering protection against rain, sleet, and even hose-directed water. Selecting the correct enclosure type is a critical aspect of maintaining the longevity and safety of any electrical installation, particularly in outdoor or industrial settings.

Compliant Installations

Adhering to electrical codes is not just about following rules; it is about guaranteeing the safety of people and property. Familiarizing yourself with the NEC Code requirements for NEMA receptacles is an essential step for anyone undertaking electrical work. Proper installation, combined with the correct selection of NEMA devices and enclosures, ensures a system that is not only functional and efficient but also fundamentally safe.

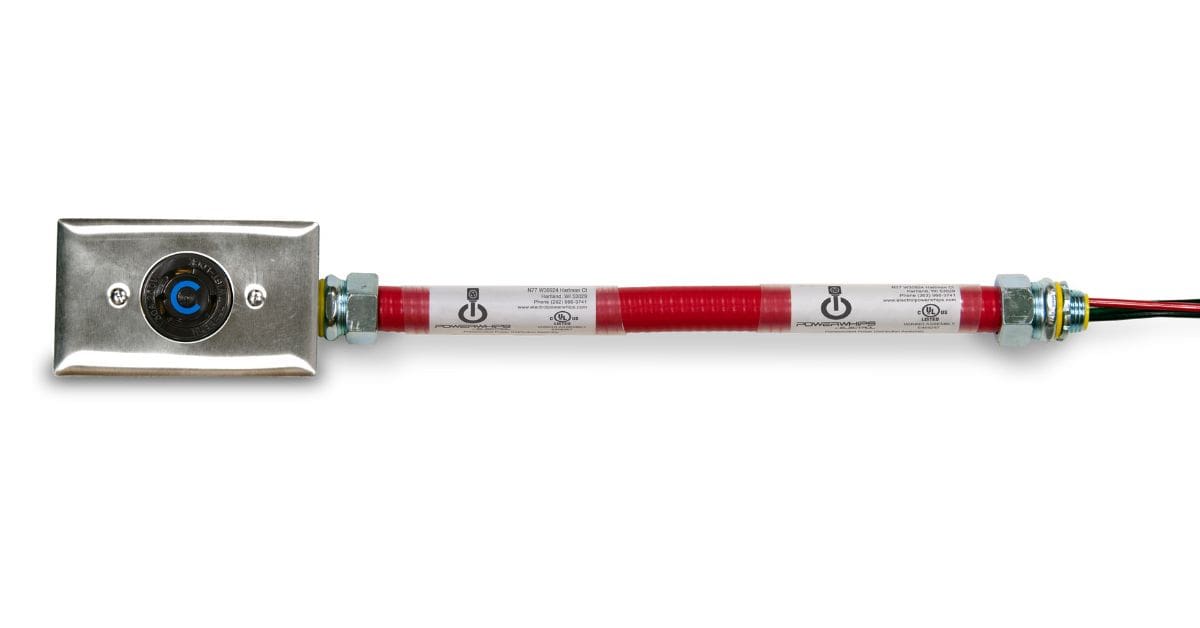

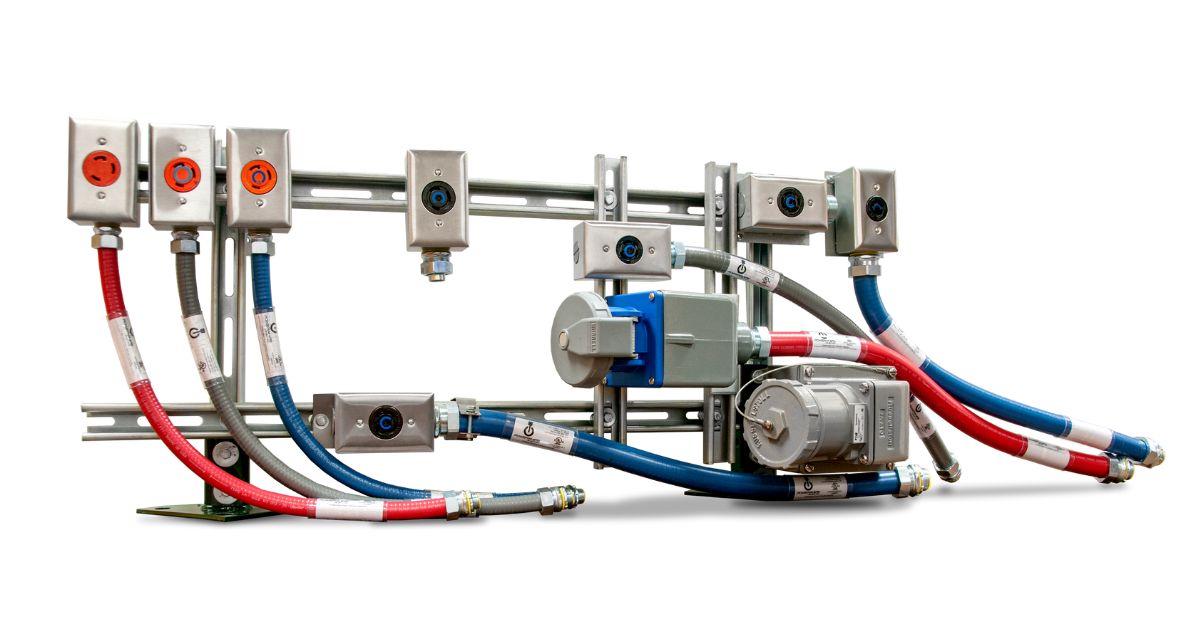

For dependable, high-quality electrical solutions, including robust NEMA power cord options that meet stringent industry standards, trust Electrol Powerwhips. Our products are engineered for superior performance and safety, ensuring compliance and reliability for your electrical needs. Explore our comprehensive selection today!