When running a food processing or manufacturing facility, the reliability, safety, and efficiency of your equipment is a top priority. This is where high-quality electrical connectors come in. Russellstoll pin and sleeve connectors meet the demands of the food industry and bring numerous benefits to food processing facilities.

What Are Russellstoll Pin & Sleeve Connectors?

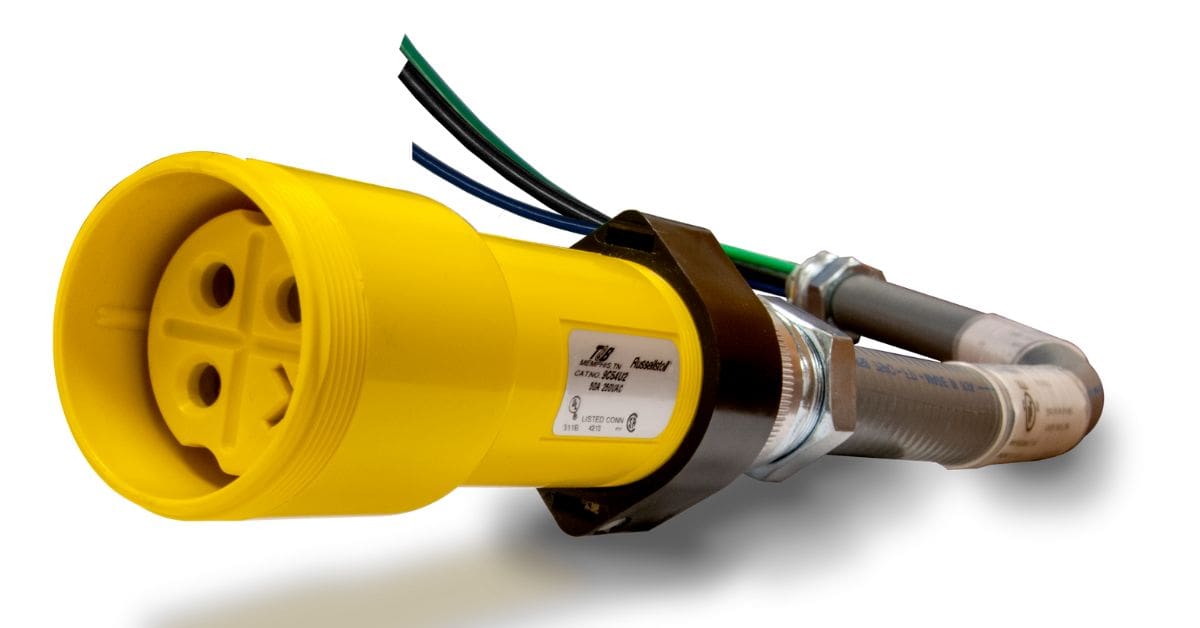

Russellstoll pin and sleeve connectors provide secure and reliable connections for heavy-duty equipment. These connectors can endure demanding conditions, so they are ideal for use in facilities with wet or corrosive environments.

One of the standout features of Russellstoll pin and sleeve connectors is their full polarization system. With this system, the plug can only be inserted in the correct orientation, aligning the voltage every time. This feature reduces the risk of electrical shocks and supports current flow.

Additionally, Russellstoll pin and sleeve connectors can withstand harsh environments thanks to the advanced sealing mechanisms and durable materials that manufacturers use for production. Due to these qualities, Russellstoll pin and sleeve connectors are a top choice for facility managers looking for long-lasting equipment.

Uses and Benefits for the Food Industry

Professionals in the food industry face daily challenges, such as maintaining hygiene standards and ensuring safe operations. Equipment in this environment must withstand rigorous conditions and contribute to seamless and efficient workflows.

Russellstoll pin and sleeve connectors are expertly engineered to meet these exact requirements. They deliver consistent power, are easy to clean, and support safety in every operation, making them an ideal solution for food industry professionals.

Waterproof and Durable

Machinery in food processing facilities requires frequent washdowns in order to comply with sanitation standards. These intense cleaning practices might involve high-pressure, high-temperature water and strong cleaning agents. All electrical equipment must be waterproof and resistant to chemicals in order to prevent workplace accidents and operational disruptions.

Russellstoll pin and sleeve connectors meet IP67 or IP69K standards, so they are waterproof. Durability is another key component for Russellstoll connectors. Due to their design, they can perform reliably, even after repeated exposure to water and cleaning agents. This reduces the risk of hazards and equipment downtime.

Easy Installation

One of the key advantages of Russellstoll pin and sleeve connectors is their straightforward installation and maintenance requirements. Russellstoll pin and sleeve connectors simplify installation through innovative designs that eliminate the need for soldering. Prioritize safety by cutting off power before attempting to install electrical connectors.

Whether you are installing new machinery or retrofitting existing equipment, Russellstoll pin and sleeve connectors are compatible and easy to use because of their standardized design. Additionally, routine maintenance is simple due to the connectors’ durable materials and modular design. Technicians can do quick inspections and replacements when necessary.

Prevents Accidental Disconnection

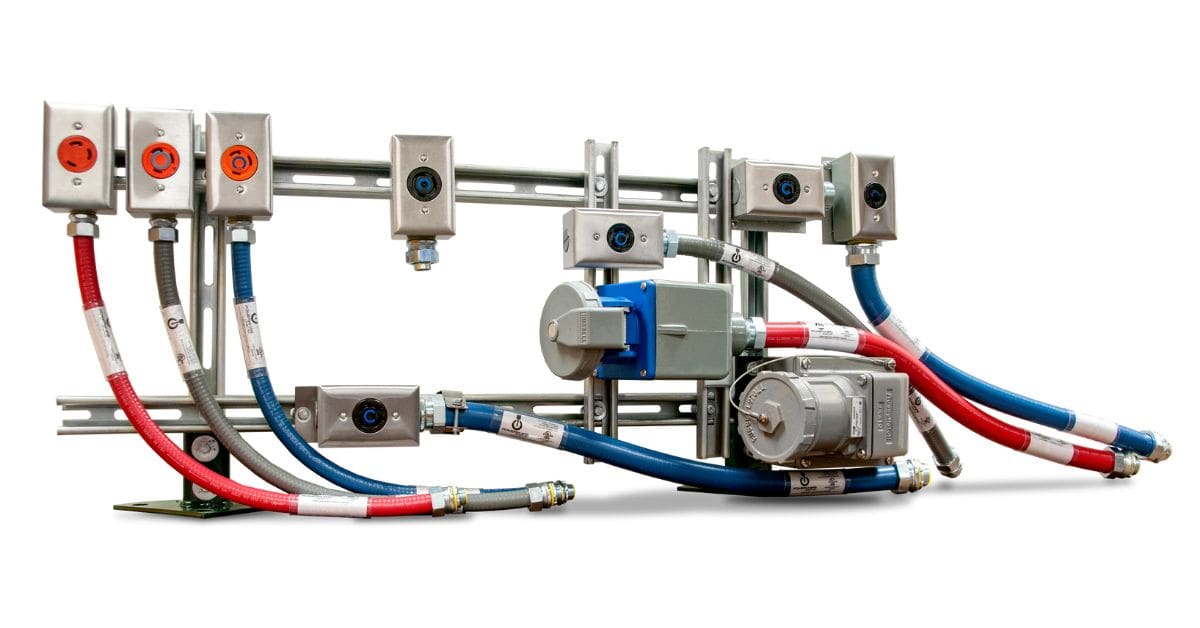

Accidental disconnections can lead to disrupted operations, increased downtime, and safety risks. The pin-and-sleeve design of Russellstoll connectors creates a secure, lockable connection that minimizes the chances of unintentional unplugging. Electrol Powerwhips offers Russellstoll pin and sleeve connectors with non-interchangeable voltage configurations, providing reliable connections while preventing mismatched ratings.

This feature is critical in food and beverage processing environments, where conveyors, mixers, and packaging systems must operate continuously to meet production demands. By preventing disconnections, these connectors maintain smooth operations, reduce employee intervention during production, and enhance workplace safety.

Resists Harsh Conditions

Work environments in the food industry can be harsh, exposing equipment to extreme temperatures, high levels of moisture, and corrosive chemicals. Electrical connectors must be able to withstand the daily challenges of these settings while maintaining reliable performance.

Russellstoll connectors consist of durable materials that can withstand multiple harsh conditions. For example, these connectors can perform reliably in environments subject to drastic temperature areas, such as freezers or ovens.

Aside from drastic temperatures, Russellstoll connectors also have specialized coatings and stainless-steel designs, which protect against rust and wear; this is crucial for the food industry due to frequent sanitization and exposure to acidic cleaning agents.

Simple Disconnection When Necessary

The pin-and-sleeve design of Russellstoll connectors ensures stability and constant electrical flow and allows for quick and easy disconnection when necessary. This feature is convenient for routine maintenance and equipment cleaning. These connectors also allow you to inspect the state of the equipment and replace parts if needed.

Workers in food processing facilities often face tight production schedules with no room for downtime, so lengthy equipment maintenance is not an option. Russellstoll connectors strike the perfect balance between secure connection and efficient disconnection to minimize disruptions to equipment.

Easy To Clean

Businesses in the food industry operate under strict safety regulations aimed at protecting consumers, workers, and the integrity of every product. Business owners and managers must adhere to these protocols, including frequent washdowns and sanitization, in order to maintain safety and earn customer trust.

However, these processes can pose challenges to the machinery, making it crucial to select equipment that is easy to clean and performs reliably. Russellstoll pin and sleeve connectors feature smooth surfaces that are easy to sanitize and maintain. These connectors also have an enclosed design, so debris and impurities cannot enter the equipment and contaminate food and beverage products.

By incorporating high-quality equipment, such as Russellstoll pin and sleeve connectors, you can confidently meet the demands of your industry’s safety regulations without compromising efficiency or product quality.

Enhancing Food Industry Operations With Russellstoll

Consumers place immense trust in companies in the food and beverage industry. They expect consumable products to be safe and free of contaminants. This trust is not given lightly, and the responsibility to uphold this trust rests heavily on food manufacturers, suppliers, and retailers.

Investing in high-quality components, such as Russellstoll pin and sleeve connectors used for the food industry, not only ensures compliance with food safety standards but also promotes operational efficiency. From preventing accidents and unnecessary downtime to enduring harsh conditions due to rigorous hygiene requirements, these connectors serve as invaluable assets to food industry professionals.

Electrol Powerwhips offers high-quality and durable Russellstoll pin and sleeve connectors that deliver the performance and reliability you need. Explore our full range of top-quality products, and see how our solutions can improve your facility’s safety, compliance, and operational flow.