Data center managers and facility operators know that reliability hinges on the smallest components. While servers and cooling systems get the glory, the power distribution architecture does the heavy lifting. Specifically, the power whips delivering electricity from the PDU to the rack must be flawless.

This is why the UL (Underwriters Laboratories) mark is non-negotiable; it signifies that the equipment has passed a gauntlet of physical and electrical stress tests. But what actually happens inside the lab? Understanding the testing procedures to certify for UL listing on power whips helps you appreciate the engineering rigor behind that holographic label on your cable assembly.

The Importance of Component Traceability

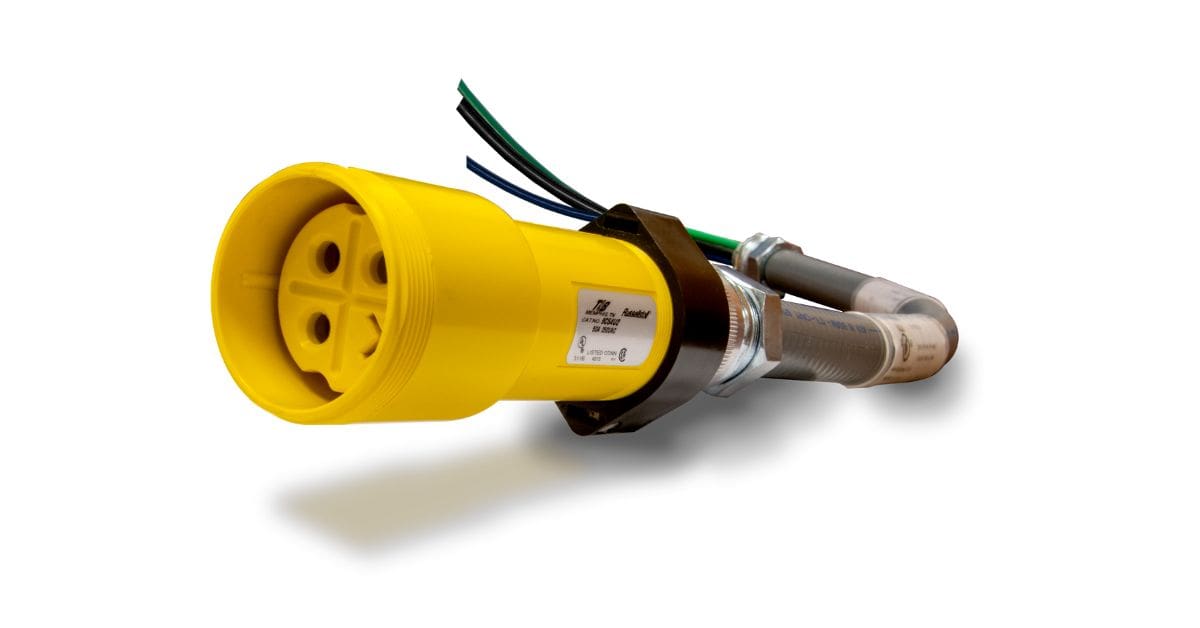

Before a single volt of electricity enters the test bench, UL engineers examine the assembly’s pedigree. A power whip is an assembly comprising a connector, a receptacle, a flexible conduit, and a wire. The certification process begins by verifying that each sub-component already holds the necessary listings.

After all, you cannot build a compliant system out of non-compliant parts. The investigative team reviews the file numbers for the plugs, connectors, and liquid-tight conduit used in construction. They verify that the wire gauge matches the amperage rating of the connectors. This strict adherence to component matching prevents bottlenecks that could cause heat buildup during operation.

Dielectric Voltage Withstand Test (Hi-Pot)

Once the construction review passes, the electrical stress testing begins. The Dielectric Voltage Withstand test, commonly known in the industry as the Hi-Pot test, is the primary method for assessing insulation integrity. The goal here is to verify that the insulation material inside the cable and within the connector housings can contain the electrical current without leaking.

For example, a whip rated for 240 volts might be subjected to 1,500 volts or more for a specific duration. The insulation must hold this charge without breaking down or allowing current to arc across to the wrong conductor. If the machine detects any current leakage through the insulation, the assembly fails.

Continuity and Polarity Verification

Power whips are impractical if they do not deliver power to the correct pins. While this may sound basic, a crossed wire in a high-voltage data center application can result in catastrophic equipment failure. Continuity testing verifies that an unbroken electrical path exists from the source plug to the receptacle.

Polarity testing takes this a step further to confirm that the path is correct relative to the pin configuration. The hot wire must go to the hot terminal, the neutral to the neutral, and the ground to the ground. In three-phase applications, maintaining consistent phase rotation (X, Y, Z) is critical for motor loads and balanced power distribution.

Grounding Impedance and Bonding Tests

Safety codes prioritize the path to ground above almost everything else. If a short circuit occurs within a server rack, that errant electricity needs an immediate, low-resistance path back to the panel to trip the breaker. If the path is blocked or has high resistance, the rack itself could become energized, posing a lethal shock hazard to anyone who touches it.

To prevent this, manufacturers perform grounding impedance tests, where a high current is passed through the ground pin and the metal conduit or casing. The test measures the resistance of this connection, and it must be incredibly low, typically a fraction of an ohm. If the resistance is too high, it means a connection is loose or painted over, which would inhibit the flow of fault current.

Strain Relief and Abrupt Pull Testing

Data centers are dynamic environments. Technicians pull up floor tiles, drag cables through trays, and reposition racks. A power whip must withstand physical wear without the internal electrical connections pulling apart. If a wire pulls loose inside the plug housing, it could cause an arc flash.

Abrupt Pull Test

UL standards require rigorous strain relief testing to address this physical reality. The Abrupt Pull test involves suspending a specific weight from the cord assembly or applying a sudden force to the cable while the connector is fixed in place.

Following the pull test, the assembly is re-examined. The wires inside must not have moved within the terminals, and the outer jacket must not show signs of tearing or separating from the connector body.

Temperature Rise Assessment

Heat kills electronics and melts insulation. When electricity flows through a conductor, it generates heat due to resistance. The Temperature Rise test verifies that the power whip operates within a safe thermal range when under a full load.

Temperature Rise Test

Laboratory technicians will connect the whip to a load bank that draws the device’s maximum rated current. Thermocouples are then placed at critical points, typically the terminal connections inside the plugs, where resistance is highest. The assembly runs at full power until the temperature stabilizes.

If the internal temperature gets too high, the insulation could degrade over time, leading to brittleness and eventual short circuits. Passing this test proves that the assembly can handle its rated load 24/7 without becoming a fire hazard.

The Quarterly Inspection Requirement

Obtaining the UL listing is not a one-time achievement. It initiates a lifetime relationship between the manufacturer and the testing laboratory. To maintain the listing, UL field representatives conduct unannounced quarterly inspections at the manufacturing facility.

During these visits, the inspector reviews production logs, calibration records for the testing equipment, and the actual assembly process. They verify that the factory continues to use the same certified components and assembly methods that passed the original evaluation.

If the manufacturer swaps a screw or changes the wire vendor to a non-listed alternative, the inspector can issue a variation notice. This ongoing surveillance guarantees that the power whip you buy today meets the same standards as the one tested five years ago.

Prevent Downtime With Certified Components

The journey to certification is exhaustive, involving verifying raw materials, stressing electrical insulation, and physically testing the final product. These rigorous steps serve a singular purpose: keeping current where it belongs and preventing catastrophic failure. When you understand the testing procedures to certify UL listing on power whips, you realize you aren’t just paying for a cable; you are investing in a verified safety system.

Electrol Powerwhips provides reliable, UL-tested, and listed power whips that seamlessly power your critical infrastructure. Whether you’re managing a data center, server room, or industrial facility, our durable solutions ensure consistent performance and peace of mind. Trust Electrol to deliver the power you need to keep operations running smoothly. Explore our products today!