Efficient power management is a crucial component of modern electrical systems, particularly in environments such as data centers, industrial settings, and commercial offices. A factor that often goes unnoticed but plays a vital role in energy performance is the length of power whips.

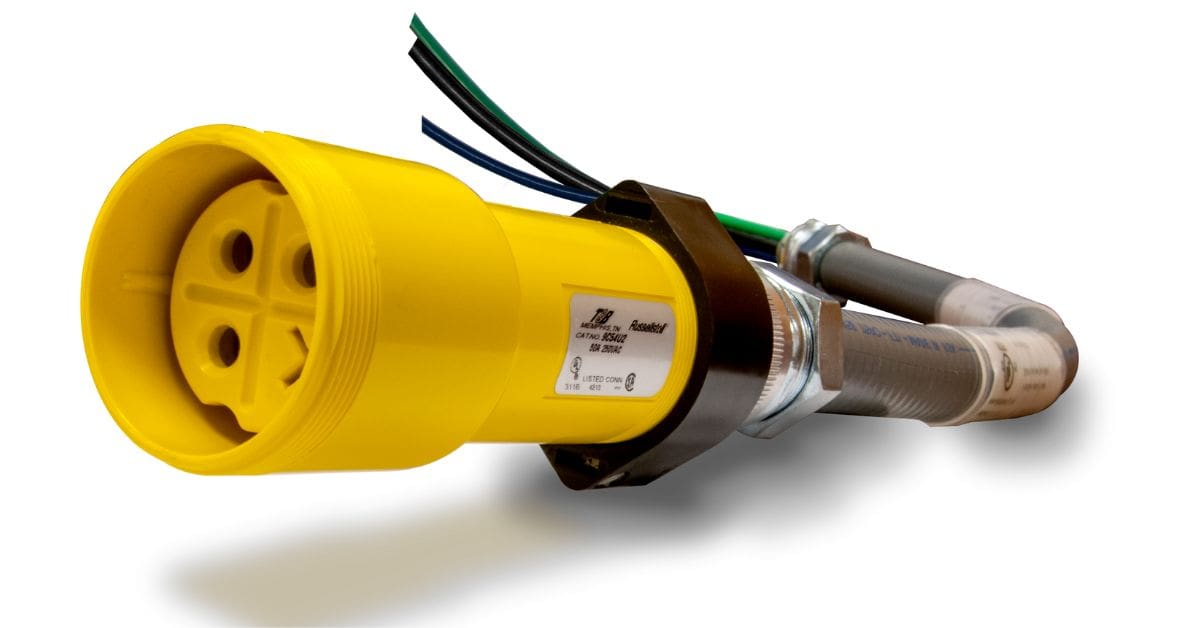

Power whips, often referred to as conduit units, deliver power from PDUs (power distribution units) to equipment, making them fundamental to transferring electrical energy effectively. The impact of power whip length on power efficiency is a subject that should not be ignored, as it directly influences energy consumption, operational costs, and equipment reliability.

Power Efficiency at Its Core

The primary objective of any power whip is to distribute electricity to devices while minimizing energy loss. However, every foot of additional length introduces more resistance in the conductor, which generates heat and leads to energy dissipation. This simple physical principle acts as the foundation for understanding how the length of power whips impacts efficiency.

Shorter power whips, with reduced conductor lengths, offer lower resistance. Reduced resistance translates to minimal energy waste, allowing the equipment to maintain optimal performance without requiring the system to compensate for voltage drops. A system designed around appropriately short power whips will not only reduce heat buildup but also enhance the overall lifespan of critical components.

Design Trade-Offs in Power Distribution Layouts

Balancing functionality and efficiency often involves making compromises in layout design. When planning electrical power distributions, the proximity of power supplies, such as PDUs, to the end devices they serve is a critical factor to consider. While longer power whips may be necessary to connect distant devices, they pose certain challenges to energy efficiency.

For instance, organizations aiming for maximized floor space utilization might prioritize placing PDUs further away from equipment racks. While this allocation supports operational workflows, it necessitates longer conduits and can result in a significant impact on power efficiency.

Shorter-length power whips, on the other hand, enable better performance but require strategic placement of PDUs. The key lies in planning configurations that strike a balance between convenience, cost, and energy efficiency. Careful mapping of layouts beforehand allows engineers to minimize whip lengths wherever possible.

Voltage Drop Management

Voltage drop is one of the most noticeable consequences of longer power whips. The further electricity travels through a conductor, the more it loses voltage energy. This reduction is particularly problematic in sensitive electrical equipment that demands a stable voltage supply.

Excessive voltage drops force devices to work harder to maintain their performance, which not only accelerates wear and tear but also significantly increases energy bills. The ability to manage voltage drops lies in understanding conductor properties, optimizing lengths, and matching the wire gauge to specific applications. Selecting the correct material and gauge mitigates many of the efficiency losses caused by longer conduits.

Proper installation practices and regular maintenance are equally crucial in addressing voltage drops. Ensuring secure connections at terminals, avoiding loose wiring, and inspecting for corrosion can significantly improve the overall performance and reliability of the electrical system, even with fluctuating loads.

Heat Buildup and Consequences on System Components

When power whips are excessively long, they face higher resistance, which produces heat as electricity travels through the conductor. This heat buildup can be detrimental to both the conduit and the surrounding equipment.

Higher temperatures within power whips significantly increase the thermal stress on their insulation and sheathing materials, potentially leading to accelerated degradation of these materials. Additionally, adjacent systems within cramped setups may suffer from reduced cooling efficiency due to the added heat output. Ensuring proper air circulation and using whip lengths that avoid overextended runs are practical solutions to maintain system-wide efficiency.

Uneven distribution of current across the conductors can lead to localized overheating, which further exacerbates wear on insulation materials and increases the likelihood of electrical failures. Regular load analysis and balancing can mitigate these risks. Furthermore, selecting power whips with appropriate current ratings and incorporating high-quality connectors can enhance reliability and extend the system’s lifespan.

At Electrol PowerWhips, we offer premium, high-quality PDU power cables designed to meet the highest standards of performance and reliability. Each cable undergoes rigorous testing to ensure durability, safety, and optimal functionality, making it a trusted choice for data centers, businesses, and industrial applications. With Electrol PowerWhips, you can count on top-rated products built to deliver exceptional power solutions.

Environmental and Sustainability Considerations

From an environmental perspective, unnecessary energy loss from inefficient power systems contributes to a higher carbon footprint. Over time, even small inefficiencies accumulate into wasted energy that negatively affects both your budget and the environment.

Adopting shorter power whips as part of energy-conscious design can reduce this impact. By leveraging energy-efficient PDUs and routing methods, businesses can make significant strides toward achieving their sustainability goals without compromising on reliability. Implementing such designs aligns corporate operations with green practices, creating additional value for both clients and stakeholders.

Simplified Maintenance and Cost Savings

Beyond energy efficiency, the strategic use of shorter power whips can significantly simplify maintenance procedures. Long power whips increase complexity by introducing more material to inspect and increasing the likelihood of disconnections or faults over time. Each connection point becomes a potential failure source, which can complicate diagnose-and-fix cycles for maintenance teams.

Simplifying layouts with shorter power whips improves accessibility to components during maintenance and repairs. This results in not only reduced downtime but also lowered operational costs. Over the lifespan of electrical equipment, the compounding savings from efficient layouts provide a strong financial incentive for businesses to invest in proper optimization of power whip lengths.

A Strategic Approach to Efficiency

Proper planning and implementation are crucial for effectively addressing the impact of power whip length on power efficiency. Businesses should conduct thorough assessments of their energy requirements, system layouts, and equipment placement to identify opportunities for energy efficiency improvements. Partnering with expert engineers and consultants who understand the nuances of electrical distribution is often a valuable step toward achieving maximum power efficiency.

Continuous monitoring of system performance further ensures that efficiency goals are met over time. Additionally, leveraging advanced tools and simulation software can facilitate the design of optimized layouts that use minimal conductor lengths. With technology advancing rapidly in this domain, organizations have more solutions at their disposal than ever before.

Invest in Smarter, More Efficient Power Management

The importance of power whip lengths in maintaining efficient and sustainable electrical systems cannot be overstated. From reducing energy losses to saving money and extending equipment lifespan, addressing whip length and layout benefits businesses on multiple levels.

By designing your systems with efficiency and reliability in mind, you can make proactive strides toward securing a competitive, energy-conscious edge. Don’t underestimate the real-world savings and operational improvements that can be achieved through meticulous design.