Power transmission is a critical component of any industrial or commercial operation, and the reliability of your power cables directly impacts productivity, safety, and equipment longevity. SO and Type W cables are widely used due to their durability and flexibility in demanding environments, ranging from construction sites to entertainment venues.

However, these robust cables can still experience power drops, leading to serious operational challenges. Understanding how to address these issues is essential for maintaining a stable power supply. Here’s a comprehensive overview for troubleshooting power drops in SO and Type W cables, with technical insights to help you diagnose and resolve problems efficiently.

Cable Inspection

A systematic physical inspection is the first step in diagnosing power delivery issues. Damage to the cable’s exterior is often a direct indicator of internal problems that can cause a drop in voltage. You should begin by carefully examining the entire length of the cable jacket for any visible signs of wear and tear.

Look for cuts, abrasions, or cracks that might expose the inner conductors to environmental factors or physical stress. Pay close attention to areas where the cable is frequently bent, flexed, or subjected to mechanical strain, as these are common failure points.

Identifying External Damage

External damage can manifest in various forms. Deep gashes may sever internal conductors, while repeated crushing can flatten the cable and compromise the integrity of the insulation and conductors. You should also check for discoloration or charring on the jacket, which could signal overheating from a poor connection or an internal short circuit. Running a gloved hand along the cable can help detect subtle imperfections, such as bulges or flat spots, that may not be immediately visible.

Assessing Insulation Integrity

The insulating material is vital for preventing current leakage and short circuits. If the outer jacket is compromised, the insulation around the individual conductors may also be damaged. Brittle or cracked insulation can expose the copper wiring, creating a risk of electrical shock and a potential path for current to escape. This can also lead to a voltage drop, especially under load.

Use a multimeter with an insulation resistance testing function to verify that the insulation meets the required specifications.

Connection Point Analysis

Faulty connections are a leading cause of power drops in portable cable systems. The points where cables connect to equipment or other cables are susceptible to wear, corrosion, and improper seating. Each connection point introduces a potential for increased resistance, which in turn causes the voltage to decrease. A thorough examination of all plugs, connectors, and terminals is a critical part of the troubleshooting process.

Connector Integrity Check

Start by visually inspecting both ends of each connector. Look for bent or broken pins, which can result from improper installation or physical impact. Such damage prevents a secure electrical connection, which can then result in intermittent power loss or complete failure. Also, check for signs of arcing, such as black or scorched marks around the pins and sockets. Arcing indicates a poor connection that is generating excessive heat and represents a serious fire hazard.

Detecting Terminal Corrosion

Corrosion at the termination points can dramatically increase electrical resistance. This is particularly common in humid or corrosive environments. Inspect the wire terminals for any signs of oxidation, which often appears as a white, green, or black powdery substance on the metal surfaces.

Corroded terminals create a high-resistance barrier that impedes the flow of current, causing a voltage drop. These connections should be disconnected, cleaned with a wire brush or appropriate cleaning solution, and retightened to ensure a solid, low-resistance connection.

Conductor and Sizing Verification

The size and condition of the cable’s conductors play a fundamental role in its ability to carry current effectively. An undersized cable or damaged conductors will exhibit higher resistance, leading to unacceptable voltage drops, especially over long distances or under heavy loads.

Confirming Adequate Gauge

Voltage drop is directly related to the length of the cable and the amount of current it carries. A cable with an insufficient conductor size for the required load will experience a significant drop in voltage. Consult the National Electrical Code or manufacturer specifications to confirm that the cable’s gauge is sufficient for the load amperage and the total run length. If the cable is undersized, the only correct solution is to replace it with a properly sized one.

Evaluating Conductor Health

Internal damage to the conductors themselves can also be a source of increased resistance. While not always visible from the outside, conductors can become frayed or broken due to repeated flexing or mechanical stress.

A continuity test using a multimeter can help identify a broken conductor. Set the multimeter to the resistance or continuity setting, and test each conductor from end to end. A cable with a fractured conductor must be replaced, as a repair is often impractical and unreliable for portable service applications.

Load and Environmental Factors

Sometimes the cause of a power drop is not within the cable itself but is related to the load it is powering or the environment in which it is operating. An excessive electrical load or extreme temperatures can affect a cable’s performance and lead to a drop in voltage.

Measuring Load Conditions

An electrical load that exceeds the cable’s rated capacity will cause a serious voltage drop and can lead to overheating. Use a clamp-on ammeter to measure the actual current being drawn by the equipment, and compare this measurement to the ampacity rating of the cable. If the load is too high, you may need to reduce the load or use a cable with a higher ampacity rating.

Considering Temperature Effects

Ambient temperature can have a notable impact on a cable’s resistance. In high-temperature environments, the resistance of the copper conductors increases, which in turn increases the voltage drop. If the cable is operating in an environment that is hotter than its rating allows, you may need to de-rate its capacity or choose a cable with a higher temperature rating.

Successfully troubleshooting power drops in SO and Type W cables requires a methodical approach that examines the cable, its connections, and the operational context in which it is used. By systematically inspecting for physical damage, verifying the integrity of connections, ensuring proper conductor sizing, and assessing load and environmental factors, you can effectively identify and resolve the root cause of voltage issues.

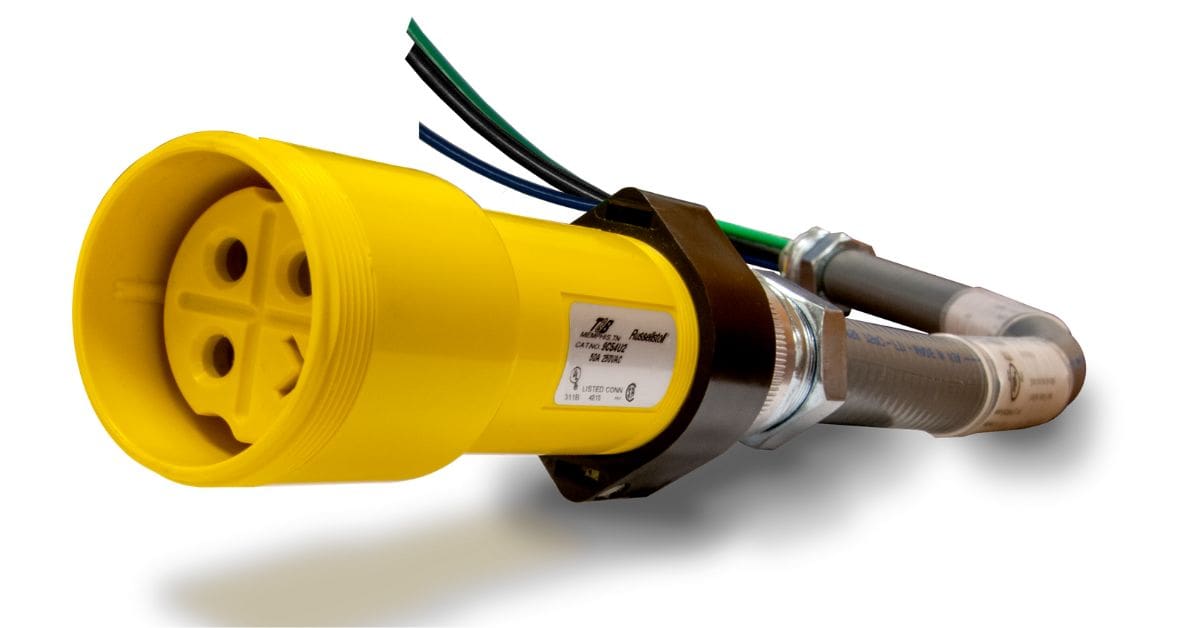

If you’re looking to replace your PDU whips, Electrol Powerwhips has you covered. We specialize in providing high-quality, durable, and reliable power cables and cords designed to deliver stable performance you can count on. Whether you’re upgrading your data center or simply need dependable power solutions, our products ensure maximum efficiency and reliability every time.