Power distribution is not a one-size-fits-all affair; it’s complex, particularly in data centers where reliability is paramount. The difference between SO and SOOW cords is essential when choosing the best option for your location. Understanding the benefits makes your decision easier and more effective in its implementation.

Overview of SO Cord

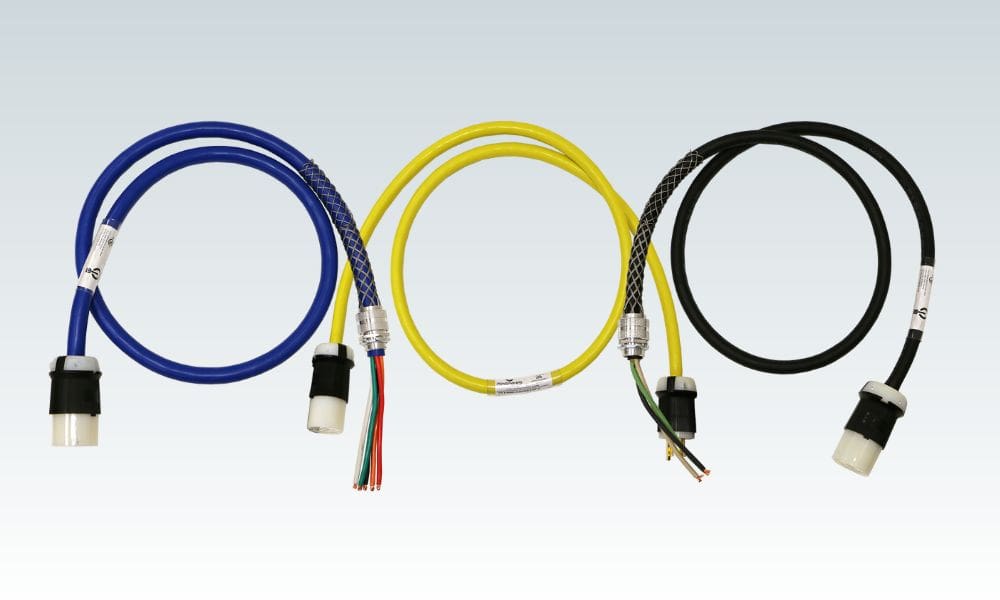

SO cord, often called service cord, is a versatile and robust cable designed to provide power in various industrial and commercial settings. Characterized by its flexible stranding and durable insulation, SO cord is manufactured to withstand exposure to oils, solvents, and varying weather conditions. The SO connector supports this resilience with a threaded end and sealing nut made of metal or a durable polymer.

Its construction adheres to the stringent standards of the American Society for Testing and Materials (ASTM), ensuring high tensile strength and exceptional resistance to abrasion and ozone degradation. This durable material is crucial for maintaining uninterrupted power flows in demanding environments such as construction sites and factory floors.

Overview of SOOW Cord

The SOOW cord meets and even exceeds rigorous industry demands, advancing the baseline features of the SO cord. With its “oil-resistant insulation and oil-resistant jacket,” denoted by the “OO” in its name, and “water-resistant” features indicated by the “W,” SOOW cord showcases superior durability against the elements.

Its rubber insulation and jacketing provide a robust shield against oil, water, and extreme temperatures, offering enhanced flexibility for easier handling and installation. Each SOOW cord undergoes meticulous engineering to comply with the National Electrical Code (NEC) requirements and the stringent Universal Laboratories (UL) standards, ensuring the cord’s capability to maintain consistent electrical integrity and safe operation in the most challenging environments.

Differences Between SO Cord and SOOW Cord

The primary distinctions between SO and SOOW cords hinge on their respective levels of durability and resistance to environmental stresses. While both cables boast a solid construction that provides a reliable power supply, the SOOW cord distinguishes itself with its superior resistance to oil and water intrusion, owing to its enhanced rubber insulation and jacketing.

This extra level of protection is pivotal in applications where the cable may experience harsher conditions, such as direct burial applications or outdoor use with exposure to the elements. The added W in SOOW reflects its water-resistant capabilities and is a key differentiator when selecting a power cord that needs to perform under adverse conditions, aligning with the NEC and UL standards. As power continuity remains at the forefront of operational concerns in industrial settings, choosing the correct power cord mitigates equipment failure and downtime risks.

The choice between SO and SOOW cords must stem from the specific demands and conditions of the intended environment. Consider these differences between SO and SOOW cords when choosing your power needs. Once you’ve decided, Electrol PowerWhips stands ready to deliver top-tier electrical solutions, surpassing industry benchmarks with cords that promise longevity and steadfast electrical performance.